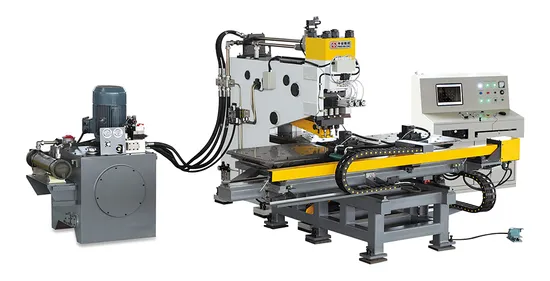

Special machine for beveling the end of H - Beams.

1. The machine is single-sided, double-sided and four-sided, each column is equipped with a three-axis milling

power head, which can install three different milling cutters. The milling head cuts both ends of H-section steel from

bottom to finish the arc groove processing of the end face, groove and web of the wing plate.

2. Double columns/four columns are installed on longitudinal and transverse NC sliding tables respectively. When

processing H-beams of different specifications, they can be adjusted automatically only by inputting machine tools with

specifications and parameters, and can milling H-beams with inclined end faces.

| Модель | BM38/6 | BM38/12 |

| Workpiece dimensions | Width of the web(mm) | 220-1000 |

| Height of the flange(mm) | 100-600 |

| Thickness of the flange(mm) | 10-38 |

| Title of the end face(mm) | ≤300 |

| The length(mm) | ≥400 |

| Three-axis drilling head | Quantity | 2 | 4 |

| Rotation speed of the spindle(rpm) | 400 |

| Power of the spindle motor(KW) | 2×7.5 | 4×7.5 |

| Up-down speed (Frequency conversion, CNC) (m/min) | 50-500 |

| Power of the up-down motor (KW) | 2×1.5 | 4×1.5 |

| Sliding table | Longitudinal slide stroke (mm) | 300 |

| Transverse slide stroke(mm) | 1050 |

| Slide Speed (Frequency Conversion, CNC)(m/min) | 150-1000 |

| Power of the sliding motor(KW) | 2×0.25 | 4×0.25 |

| Vertical clamper | Vertical clamping speed(m/min) | 450 |

| Power of the vertical clamping motor | 2×0.37 | 4×0.37 |

| Gas-liquid boost device | Boost ratio | 11:1 |

| Clamping force | 3.5-8 |

| Automatic milling deep iron | Amount of regulation | 0-40 |

| Power of the motor | 2×0.04 | 4×0.04 |

| Outer and inner roller conveyor | Length of outer roller conveyor (mm) | 1×5060 | 2×5060 |

| Conveying speed (Frequency conversion) | 2.5-20 |

| Power of the outer conveyor motor(KW) | 0.75 | 2×0.75 |

| Power of the inner conveyor motor(KW) | 0.4 | 2×0.4 |

| Power of the motor for supporting roller(KW) | 2×0.09 | 4×0.09 |

| Power of motor for titling roller conveyor | | 4×0.09 |

| Size of machine (L ×W×H) (m) | 7.3×2.9×2 | 14.6×2.9×2 |

| Weight of machine (kg) | 5000 | 10000 |