|

US$200,000.00-1,000,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Model NO.

DMK-G5R22-108-20

After-sales Service

Engineers Fly to Clients′ Factory

Bottle Type

Round or Square

Cap Type

PE Screw Cap, Crown Cap, etc.

Transport Package

Wooden Case

Specification

Stainless Steel

Production Capacity

18000 Bp/H- 60000 Bp/H

Packaging & Delivery

Package Size

915.00cm * 760.00cm * 320.00cm

Package Gross Weight

18000.000kg

Product Description

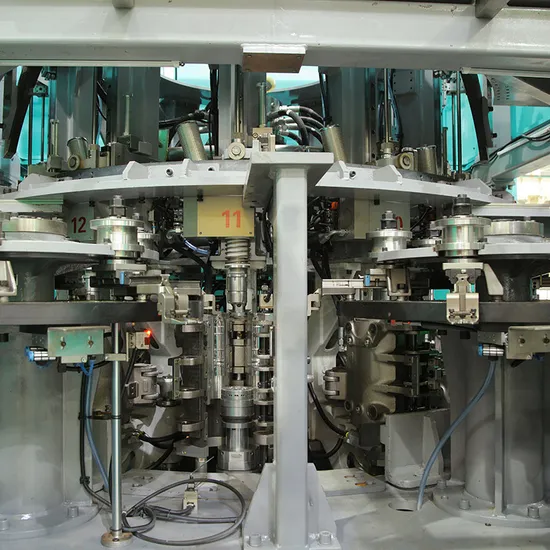

Demark Bottled Lemonade Blowing Filling Capping Combiblock

General Description

Demark Lemonade Blowing Filling Capping Combined Machine, a cutting-edge solution designed to revolutionize the production process of soda water and soft drinks. This state-of-the-art machinery combines the functionalities of a soda water combiblock, soda water bottle blower, and soft drink filling machinery, offering unparalleled efficiency and productivity for your business.

With its advanced technology and precision engineering, the machine ensures seamless and reliable operation, delivering high-quality products consistently. This machine is specifically designed to cater to the demands of the B2B sector, providing a formal and professional solution for your production needs.

Working Process

1. Blowing Unit The blowing process of this production line utilizes the latest techniques to create high-quality plastic bottles. By employing precise control and superior materials, it ensures the bottles are sturdy, durable, and perfectly shaped. This attention to detail guarantees that your products will be presented in an appealing and professional manner, leaving a lasting impression on your customers.

2. Filling Unit The filling stage of the combiblock system is designed to maintain the purity and integrity of your mineral water. With its advanced filtration and sterilization mechanisms, it eliminates any impurities or contaminants, ensuring that only the highest quality water is packaged. This not only enhances the taste and freshness of your product but also instills confidence in your customers, knowing they are consuming a safe and healthy beverage.

3. Capping Unit The capping process of this production line is engineered to provide a secure and leak-proof seal. With its precise torque control and reliable capping mechanism, it guarantees that your bottles are tightly sealed, preserving the freshness and quality of your mineral water. This attention to detail ensures that your customers receive a product that meets their expectations every time.

Technical Parameters

| ITEM | UNIT | DMK - G5R22-108-20 |

| Blowing Cavity | | 22 |

| Filling head | | 108 |

| Capping head | | 20 |

| Productivity | bottle/h | 36000 |

| Volume | L | 0.2-2 |

| Material | | PET |

| Diameter of bottle | mm | 50-105 |

| Height of bottle | mm | 150-310 |

| Power | | 380V50Hz |

| Installation power | KW | 18 |

| Dimension of main machine | mm | 9150×7600×3200 |

| Weight | KG | 18000 |

| | | |

Technical Features

The blowing filling capping combiblock is a game-changing technology that is set to revolutionize the bottling industry. With its innovative design, advanced features, and numerous benefits, it is the perfect solution for any beverage manufacturer looking to improve efficiency, reduce costs, and enhance product quality.

1. Reliable and efficient design. The filling machinery aspect of this machine guarantees accurate and efficient filling of your beverages. With its precise control system, you can adjust the filling volume according to your specific requirements, ensuring consistency and minimizing wastage. This feature is particularly beneficial for businesses that offer a wide range of soft drink flavors and sizes.

2. Ease of use. It is designed to be user-friendly, allowing operators to easily adjust settings and make quick changes without interrupting the production process. This makes it an ideal solution for businesses of all sizes, from small-scale productions to large industrial plants.

3. Highly flexible and versatile. It can be adapted to produce different bottle sizes and shapes, allowing manufacturers to respond to changing market demands.

4. Easily integrated with existing production lines. The combiblock feature of this machine allows for the simultaneous blowing, filling, and capping of bottles, streamlining the production process and maximizing output. This integrated system eliminates the need for multiple machines, reducing space requirements and minimizing operational costs.

5. Highest standards of quality and durability. It utilizes advanced technology to produce high-quality bottles with precision and consistency. This ensures that your products are packaged in durable and visually appealing containers, enhancing the overall presentation and appeal of your brand.

In conclusion, the Demark Lemonade Filling Machine is the ultimate solution for businesses in the B2B sector seeking to enhance their production capabilities. With its soda water combiblock, soda water bottle blower, and soft drink filling machinery functionalities, this machine offers unmatched efficiency, reliability, and precision. Invest in this cutting-edge technology and elevate your production process to new heights.

Company Profile

>>

KCK Meat Tagging gun Hand tools

>>

Newly Arrival Mens polo t shirts

>>

MAICTOP auto body kit car bumper grille 3 lens headlight for lx570 2008-2012 upgrade to 2013-2015 kits

>>

Centrifugal Oil Filter Machine

>>

Ts-1700 Disposable Lunch Plastic Box Food Container Making Machine Injection Molding Machine

>>

Ductilometer for Force Ductility Test of bituminous materials

>>

Mindvision High Speed 10gige Industrial Camera Imx421 408fps 2.8 Mpc-Mouth 2/3 CMOS Area Scan Machine Vision Digital Camera

>>

Pulse Laser Cleaner Suitcase Type Pulse Laser Cleaner for Rust Removal

>>

Blackout Zebra Blinds Hotel Project Vision Blinds

>>

Universal Milling Machine X8126 for Processing Small and Medium Molds

>>

Organic Waste/City Garbage Shredder Two Shaft Shredding Machine

>>

Blade For Crushing Plastic Tire

>>

Qlent Manufacturer Good Qualiy Air Filter 9L8z-9601-a for Ford 9L8z-9601A 9L8z9601A

>>

Livestock Machinery Husbandry Machines Advanced Climate Control System Environment Production Equipment for Swine House Odor Cleaning System

>>

PVC Floor Extrusion Machine Spc Vinyl Flooring Making Machine

>>

T3 Series DN15-DN40mm Single Channel Small Ultrasonic Water Meter Battery Operated Ultrasonic Water Metering

>>

Custom Shock Absorber Hollow Shaft How Piston Rod with High Quality and Wholesale Price

>>

100 Ton Deep Drawing Hydraulic Press Machine for Sheet Metal Forming

>>

High Quality Polyester Rayon Linen Fabric Printing for Shirt Fabric

>>

Food Commercial Fried Roll Ice Cream Making Machine