Product Details

Product Description

Product Description

Specification

| Frame capacity | 2000kg |

| Load cell brand | Germany brand load cell for high accuracy, |

| 2000kg (500,1000kg are optional) |

| Load accuracy | 0.5% F.S |

| Control system | PC with windows 7 system |

| Motor | Panasonic servo motor w/AC variable speed drive system, high-precision mechanical ball screw rod |

| Force reading | kgf, Ibf, N, KN, T etc |

| Vertical test space | 1200mm including fixture |

| Horizontal test space | ≤400mm |

| Test speed | 0.1~500mm/min (adjustable) |

| Software | TM 2101 |

| Curves display | Load- elongation, Elongation-time, Time-elongation, Stress-strain |

| Data display | Max. force, speed, sample information, strength(Kpa, Mpa, N/mm, N/mm2) etc… |

| Safety features | E-Stop |

| Over-load protection |

| Upper and lower limit switches |

| Load sensor with automatic retreat |

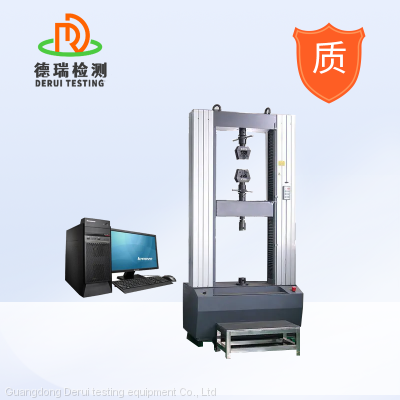

One-button operation tensile strength tester: efficient and accurate solution for mechanical property testing

I. Equipment Core Overview

One-touch operation tensile strength tester is an all-in-one equipment designed for material mechanical property testing, integrating computer control, automatic measurement, data acquisition, real-time display and result analysis. Its core objective is to simplify the operation process, for metal, non-metal and composite materials to provide fast and accurate tensile strength, yield strength, fracture strength and other key parameters of the test, applicable to scientific research, production and quality inspection and other scenarios.

Two, one-button operation: minimalist process and efficient experience

Simplified process

Users can start the complete testing process with a single keystroke, and the system automatically completes parameter configuration, test execution and data collection without complex manual intervention.

Improved Efficiency

One-button operation reduces test preparation time, supports continuous execution of batch test tasks, and significantly improves test throughput per unit of time.

Operational universality

Intuitive interface design reduces the technical threshold, non-professionals can operate independently after simple training, reducing the dependence on professional engineers.

Analysis of Core Functions

Multi-mode testing capability

Support tensile, compression, bending, shear, peeling, tearing and other mechanical properties test, a machine to meet the needs of diversified material testing.

High-precision Measuring System

Adopting high-precision force transducer and displacement encoder, combined with intelligent filtering algorithm, to ensure the accurate capture of small deformation and load change.

Real-time data visualization

Through the high-definition touch screen or PC software real-time display of load-displacement curve, stress-strain distribution and other key data, support dynamic monitoring and abnormal warning.

Intelligent Data Analysis

Built-in professional analysis software automatically generates test reports, including statistical parameters, curve comparison, fracture characterization and other functions, supporting data export and customized report templates.

Fourth, the industry application panorama

Material research and development: rubber, plastic, composite materials and other new materials performance verification

Manufacturing industry: metal parts strength testing, wire and cable tensile performance assessment

Quality inspection: textile fiber strength testing, packaging material tear resistance verification

Research and education: research on mechanical properties of materials, teaching laboratory equipment

V. Technical Advantages of Equipment

Accurate and reliable

Certified to ISO/IEC 17025 calibration standard, ensuring international mutual recognition of test data.

Safety Protection

Equipped with multiple safety mechanisms such as overload protection, emergency shutdown, displacement overrun, etc. to ensure operational safety.

Intelligent Expansion

Support modularization upgrade, compatible with high temperature, low temperature, corrosion and other special environment test module.

Operation and Maintenance Guide

Standardized operation process

Specimen installation: select the appropriate fixture according to the type of material, to ensure that the clamping centering

Parameter Configuration: Preset test speed, load threshold and other key parameters.

One-button start: start the test after confirming safety, and the system automatically completes the whole process.

Preventive maintenance strategy

Regular calibration: Calibrate sensors and displacement systems according to measurement specifications.

Cleaning and maintenance: Regularly clean mechanical parts such as fixtures and guide rails.

Software update: Upgrade the control software in time to obtain new functions and performance optimization.

Through intelligent design and modularized architecture, the equipment realizes the precision, efficiency and universality of mechanical property testing, providing reliable technical support for material research and development, quality control and scientific research and innovation.

>>

Factory OEM Bolsas De Cafe Box Bottom Mylar Stand Up Pouch Aluminium Foil Bean Coffee Bag With Valve

>>

Car Plastic Front Bumper Bracket Support Retainer For Prius C AQUA 2012 - 2014

>>

Floral printed Women Summer Beach Dresses Printed Women Tunic Top Elegant style simple look manufacturer Australia

>>

1 1/4" Galvanized Coil Roofing Nails

>>

China High Speed Automatic Bar Solid Soap Packaging Machine,Small Hotel/Home Bath Soap Packing Machine

>>

220V High-Performance Wire Rope Electric Winch for Heavy Lifting

>>

OEM CNC Fuel Cap Handle Spring Rod Stainless Steel

>>

modern design windows and sliding doors double glazed soundproof balcony with screen aluminum interior noiseless sliding door

>>

JDEC JICHAI JINAN DIESEL ENGINE 6000 DIESEL GENERATING SETS spareparts

>>

Natural Gas Forged Steel Ball Valve

>>

spirit of the cache coins

>>

high quality car spare parts front grille for FORD MONDEO 2013

>>

OEM brand logo PVC Rubber Beer Bar Mat Eco Water proof PVC Drinking Bar rail mat silicone bar mat spill bar mat

>>

2025 New Product Raycus Jpt 20W 30W 50W Desktop Optical Fiber Laser Marking Machine Price for Metal

>>

Z40 Z60 Z150 Regular/Big/Zero Spangle Hot Dipped Gi Gp Galvanized Steel Plate Coil

>>

1500w Automatic Exchange Table bed Fiber Laser Cutting Machine

>>

Aluminum Alloy Roller Beeswax Foundation Machine Bees Foundation Mill

>>

85-99.95%C Flake Graphite Expandable Graphite 180- 350ml/G for Fire Retardant EPS Foam /Natural Flake Graphite Powder/Amourphous Graphite/Crystalline Graphite

>>

TWS Earphone Wireless Bt Earbuds Pro 3

>>

250GSM Nylon Spandex Double Knitted Fabric with High Stretch for Sportswear/Yoga Wear/Legging