|

US$8,500.00-35,000.00

|

1 Set

(MOQ)

|

Basic Info.

Plastic Type

Thermoplastic

Plasticizing Way

Screw Type

Computerized

Computerized

Certification

CE, ISO9001:2008, TUV

Place of Origin

Guangdong, China

Injection Weight (G)

120 G

Showroom Location

Viet Nam

Plasticizing Capacity(G/S)

120

Warranty of Core Components

1 Year

Injection Rate (G/S)

120 G/S

Mold Height(mm)

150 - 250 mm

Video Outgoing-Inspection

Provided

Key Selling Points

High Productivity

Machinery Test Report

Not Available

Transport Package

Wooden Box

Specification

180cm/120cm/260cm

Origin

Guangdong Dongguan

Product Description

Product Description

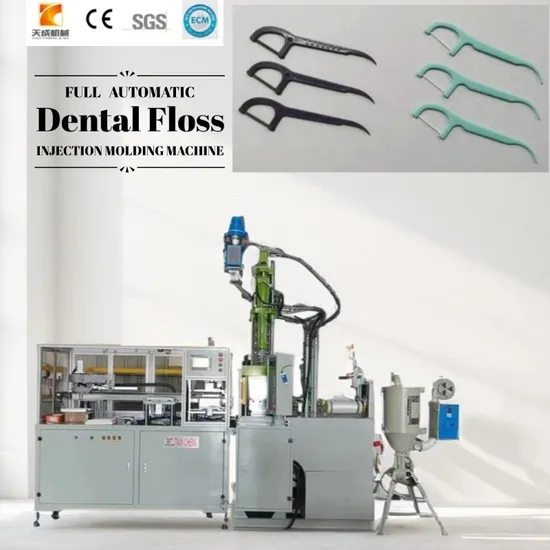

| Brand Name | Tiancheng | | Style | VERTICAL |

| Condition | New | | Model NO. | TC-1200-P |

| Screw Diameter (MM) | | | Max.Hydaulic Pressure(Kg/cm3) | |

| Maximum injection Pressure (Kg/cm2) | | | Pump Output (L/min) | |

| Theoretical Shot Volume (Cm3) | | | Oil Tank Capacity (L) | |

| Maximum Shot Weight (G/oz) | | | Cooling Water Consumption(L/H) | |

| Injection Rate (Cm3/sec) | | | Electric Power (KW) | |

| Screw Speed (R/Min) | | | Total capacitance (KW) | |

| Screw Rate (MM) | | | Total Wattage (KW) | |

| Nozzle Retraction Stroke (MM) | | | Machine Specification(M) | |

| Clamping Force (Ton) | | | Weight of Machine (KG) | |

| Opening Force (Ton) | | | Plastic Processed | PP, ABS, FRPP/PVC, PE, ABS/PP, PE/PP |

| Platen Size (MM) | | | After-sales Service Provided

| Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support |

| Distance Between Tie-Bere (MM) | | | After Warranty Service

| Video technical support, Online support, Spare parts, Field maintenance and repair service |

| minimum Mold Thickness (MM) | | | Warranty | 1 year |

| Opening Stroke (MM) | | | Applicable Industries | Manufacturing Plant, Construction works , Energy & Mining, Other |

| Max-Distance opening mold (MM) | | | | |

| Max.Mold Size | | | | |

| Ejector Force (Ton) | | | | |

| Ejector Stoke (MM) | | | | |

Welcome to Dongguan Tiancheng Machinery Co., Ltd

Embark on a journey with Dongguan Tiancheng Machinery Co., Ltd, established in 1999, proudly celebrating over 26 years of relentless innovation. Our sprawling 15,000-square-meter facility is a testament to our expertise in crafting a diverse array of cutting-edge injection molding machines. Our global footprint spans across numerous countries, showcasing our prowess in international sales and our commitment to exceptional after-sales service.

Our dedicated team of professional engineers is at your service, ready to design bespoke vertical injection molding machines that perfectly align with your unique specifications. Should you seek customization, kindly share the following details with us for optimal service:

1) What are the mold dimensions? Can you provide any product images or detailed drawings/specifications?

2) How many pieces are produced per mold? What is the weight of each piece?

3) Which materials will be utilized in production? Options include Rubber, PP, ABS, PE, PVC, TPE, TPU, POM, PA66, PBT, PS, Glass Fibre, HDPE, among others.

Customizable service!

Harness the power of our customization services, designed to adapt our machinery to align with your specific requirements. Please provide the following information to initiate the process:

1. Mold dimensions

2. Product images

3. Detailed product drawings/specifications

4. Quantity produced per mold

5. Product weight per piece

6. Material selection for production

Product quality control details:

In our factory, the meticulous control of production details ensures the delivery of exceptional manufacturing equipment to our clients!

1. Our machines can be equipped with either single-mode skateboards or an alternating dual-mode skateboard.

2. Safeguard your operations with a low-pressure mold clamping device, prioritizing security.

3. The lower mold, fixed onto the movable mold, ensures precise positioning of insert items and includes a finished product top-out feature.

4. Experience precise molding with three-stage temperature control, fast adjustments, and seamless back-pressure and screw-speed regulation for diverse plastic applications.

5. The tube features a convenient lift for easy cleaning and material handling, simplifying fixed mold operations.

6. An in-line screw type injection apparatus enhances performance.

MULTILINGUAL

Our machine's computer interface can be programmed in:: Chinese, English, Korean, Russian, Arabic, Polish, Thai, Turkish, Spanish, and Vietnamese.

This multilingual capability empowers users worldwide to operate the machine with ease.

Product Highlights:

BIG INJECTION

Setting new standards with our 'big' injection cylinder, distinguished by its substantial injection pressure and expansive sectional area. This heightened

injection pressure ensures flawless products free of sink marks, while the enlarged sectional area delivers consistent and stable pressure for seamless machine operation.

DOUBLE INFRARED SENSOR

Equipped with a double infrared sensor, our machine offers an extended range of safety measures. It ensures optimal protection for operators, halting operations if a worker's hand is detected within the sensor's range during injection, with the upper platen automatically retracting.

Certificate display

Our award-winning designs have earned numerous certifications, empowering our clients to surpass industry standards in production efficiency and innovation!

Service, service, service!

Following a thorough examination, Dongguan Tiancheng Machinery Co., Ltd. extends a 12-month quality guarantee for our unparalleled Productive Toothpick Making Machine for Streamlined Dental Floss Operations. During this period, we offer complimentary wearing parts and provide other components at the most competitive prices. To ensure optimal performance, it is essential that the buyer's technicians operate and maintain the equipment in alignment with our specified guidelines, addressing any minor issues that may arise.

Should you encounter challenges in resolving issues, our dedicated support team is ready to assist you via telephone guidance. If the issues remain unresolved, we will dispatch a qualified technician to your facility to provide hands-on solutions. For comprehensive details on the cost of technician deployment, please refer to our technician cost treatment method.

Our commitment to quality assurance includes robust technology support and exceptional after-sales service. We offer wearing parts and additional spare components at preferential rates. Post the quality guarantee period, it remains imperative for the buyer's technicians to adhere to our operational and maintenance standards, adeptly troubleshooting any faults encountered.

If technical difficulties persist, our expert team will offer immediate assistance via telephone. For problems that are not resolved through remote guidance, we will arrange for a technician to visit your premises and ensure a satisfactory resolution.

Shipping method

Recognizing that many of our esteemed clients purchase multiple pieces of equipment, we prioritize offering FOB pricing and facilitate delivery to the customer's chosen port in China. This ensures a seamless and cost-effective shipping experience. However, we are also pleased to accommodate our customers' needs by providing DDP pricing. Kindly engage in discussions with us to tailor the shipping agreement to your specific requirements.

Tips:

We take meticulous care to safeguard your machinery, ensuring every component of our machine is meticulously coated with protective oil. This layer of defense prevents corrosion during maritime transport, guaranteeing that upon arrival, the machine is fully operational and ready to perform flawlessly.

F&Q

1. How to choose injection molding machine?

To select the ideal injection molding machine, the injection weight should approximately exceed the product's weight by 20%. Additionally, ensure the tie bar space surpasses the mold dimensions. For in-depth consultation, reach out to our experts.

2. How to pay?

We require a 50% deposit via T/T in advance, with the remaining 50% balance due by T/T prior to delivery. We accommodate various payment methods, including T/T and L/C.

3. Is it possible for your company to send an engineer to install the machine for commissioning and train our workers?

Absolutely, we can deploy our engineers to your facility for comprehensive installation, commissioning, and staff training. Our seasoned engineers frequently travel across countries to provide exceptional after-sales service and technical assistance. Typically, the entire process takes 5-15 days, contingent on preparations, such as an invitation letter for the visa. Please note that all expenses related to travel, accommodation, and visa must be settled in advance by the customer, and we cannot guarantee visa approval.

4. If we buy your machines, is there any warranty?

Indeed, we offer a comprehensive 12-month warranty post-shipment for mechanical components. Should any parts fail within this period, we will provide replacements free of charge, although transportation costs will be the responsibility of the client.

5. Do you have reference projects?

We have established reference projects across numerous countries. With the consent of our clients, we can share their contact details for you to visit their facilities. Additionally, we warmly invite you to tour our company and witness our machines in action; we offer complimentary transportation from the nearest station.

Feel free to connect with our sales team to receive videos showcasing our machines in operation, offering you a glimpse of their superior performance and reliability.

Contact our sales team to access comprehensive video demonstrations of our reference machines in action.

6. Do you provide customized service?

Our expertise allows us to tailor machines to your specific requirements, including material, power, and filling type. Alongside our customization service, we provide professional recommendations, drawing on our extensive industry experience to enhance your operations.

7. What's your guarantee or the warranty of the quality if we buy your machines?

We are dedicated to delivering top-tier machines with a solid 1-year guarantee, alongside a commitment to providing lifelong technical support, ensuring enduring performance and peace of mind.

8. How long does the installation process take?

Depending on your specific machine order, we will dispatch one or two of our highly skilled engineers to your facility. The installation process typically spans from approximately 10 days up to 25 days, ensuring a seamless and efficient setup tailored to your operational needs.

>>

AA8XF06 Stock SMT FUJI NXT H04S 15.0G Nozzle for pick and place machine

>>

Woodworking Machinery Automatic CNC Panel Saw

>>

ABS 2 in 1 Set 360 Rotation Air Vent Dashboard Mobile Stand Car Phone Holders for Car Mount

>>

Hot Sale Agricultural Machinery Poultry Equipment Silage Corn Harvester with 2300mm Height

>>

4Pcs Universal Anime Car Fiber Auto Door Handle Film Dome Sticker For Car Protect Body Car Sticker Anti Scratch Vinyl

>>

High Quality SMC Composite Telecom Square Sealed Manhole Covers FRP Fiberglass Round Manhole Cover and Frame Plastic Polyester Resin Waterproof Manhole Cover

>>

Custom Manual Meat Patty /Hamburger Cake Press To Spread The Meat Machine

>>

Long Distance Full Color Fixed Outdoor LED Display Adapt to Harsh Environments

>>

Yl-852wl Digital Wireless Door Bell

>>

Qlent Manufacturer OEM Quality Air Filter 17801-45031 1780145031

>>

Customized Ivory Cap Sleeves Ball Gown Wedding Dress with Cathedral Tail

>>

High Quality Sodium Bicarbonate 99% Food Beverage CAS 144-55-8 Factory Price

>>

Buy Xiaomi 12 PRO Only $329 at Gizsale.com

>>

Thermal Bond Nonwoven Fabric Making Machine/Hg-3200s

>>

Green Screen Photography Backdrops Polyester Professional Background for Photo Studio

>>

Automatic Edge Chamfering Stone Cutting Machine for Granite, Marble, Porcelain, Quartz

>>

8cbm Mixer Drum Concrete Mixer Tank Cement Mixers Bucket Export to Philippines

>>

Air Tight Inflatable Snow Fort Igloo Tent

>>

Custom American Men's Letterman Jacket Real Leather & Thick Wool Baseball Collages Jackets Chenille Embroidered patch work

>>

Large Package Waterproof Outside Metal Steel Letter Mail Mailbox Post Wall Mount Outdoor Smart Parcel Delivery Drop Box