Product Details

Product Description

Product Description

Titanium is a high strength low density metal, with high corrosion resistance. Titanium can be welded, machined and formed the same as any other steel. Titanium has a melting point temperature of 1668°c which is greater than steel yet titanium weighs almost half that of stainless steel. Due to its unprecedented strength and non-corrosive characteristics, titanium is the metal of choice for engineers in the aerospace, petrochemical and medical industry. The higher strength of titanium enables engineers to use thinner materials, which in turn saves material costs and handling charges.

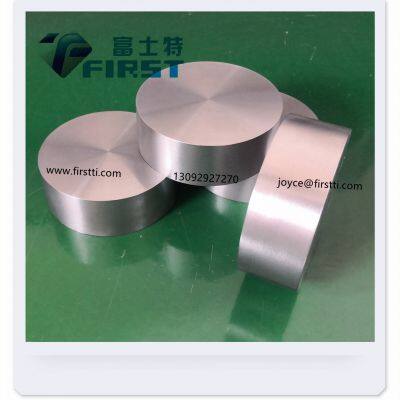

Titanium Disc(Thin Thk, Heavy Thk)

Water jet cutting to precision size is available, and free of oxide.

Specification: ASTM B265, ASTM B348, ASTM B381

Diameter Maximum 2500mm & Custom sizes are available

Grades: F1, F2, F5, F7, F12

Finished: Cold rolled with bright, smooth surface.

Test: Ultrasonic test, dyeing test, Hardness test.

Applications: Offshore, chemical processing and medical using.

Applications:

Mechanical equipment, chemical equipment, electroplating equipment, medical equipment, various precision machinery parts and related industries with high precision requirement on titanium bars.

State supplied: hot processing state (R), cold processing state (Y), and annealed state (M)

Packing: Baled, or packed in the wooden case

Chemical Component: (Nominal %)

Surface treatment: Polishing or lathing

Surface quality: The surface has high accuracy and is clean and smooth. No oxidized layers. No pits, cracks, backfins, rolling skins, lumps, laminations, hair cracks and other defects.

Physical properties: Better elongation and strength

Test: Test on physical properties, hardness test and test on chemical ingredients.

Production technology:

Flow of rolling production: hot forging – hot rolling – alignment – heat treatment – lathing (polishing) – physical and chemical tests – rating – warehousing.

Quality control during production process:

We use the first-class rolling mill and four-way high-speed forging machine for titanium bars. The production process strictly complies with relevant standards.

Contact Us:

Phone: +86 130 9292 7270

Email: joyce@firstti.com

>>

Movable Vertical Oil Tank Shell Shot Blasting Machine

>>

MAICTOP car exterior accessories body kit rear bumper for hilux revo 2016 factory price 52159-0K290

>>

Factory sell candle wax filling machine with stock price

>>

New Energy Vehicles Ev Charging Cable Type 1 Plug EV 16A/32A Car Charger SAE J1772

>>

High Quality Factory Custom Left Right 12" 10" X 2-1/4" Electric Trailer Brake Assembly

>>

Gray Elastic Knitted Cuffs Polyurethane Palm Dipped Coating Top Fit Gloves White PU Assembly Safety Work Hand Gloves

>>

Tasty Sriracha Coated Black Soya Beans OEM Available Kosher Snacks

>>

Best Selling China Powder Compound Phosphate K770 Food Grade

>>

Standard Hospital SMS Surgical gown Medical Disposable Waterproof Gown sterile

>>

Dia. 200*50mm Sieved Screen Stainless Steel Sieve Mesh

>>

PLC Control Low Pressure Conveyor Type PU Pouring Machine

>>

magnesium ingot 99.95%

>>

Semi-Chrome Grille Front Bumper Kidney Grill for bmw 5 Series E60 51137065701

>>

HONGXIN Industrial chicken meat slicing machine poultry / chicken cutting machine

>>

WEIKA Casement awning casement tilt-turn window aluminum black frame double glass windows

>>

4 shaft shredder supplier in china

>>

High Speed A4/A3 Paper Roll to Sheets Cutting Machine (One Roll Feeding)

>>

Bulk LPG Gas Storage Horizontal Propane Tanks for Sale

>>

Big Size Sleek General Edge Wash Basin for Bathrooms 5414 Series

>>

Mens Straight Blades Safety Razor Brass Stainless Steel Double Edge Shaving Razor